Master the Art of Lap Joints: Types, Uses, and Expert Tips

A lap joint is a type of joint where two or more boards overlap each other, creating a connection at the point of overlap. This joint is commonly used in woodworking, metalworking, and construction, providing a simple and efficient method for joining materials. The overlap can be achieved through various techniques, such as cutting a notch or groove in one or both pieces, resulting in different types of lap joints, including basic lap, half-lap, and dovetail lap joints. Lap joints are fastened together using mechanical fasteners like nails, screws, glue, wooden pegs, or dowels. While the basic lap joint is not very strong, other variations, such as the half-lap joint, offer increased surface area for glue and lateral strength, making them more suitable for woodworking projects and cabinetry. Overall, lap joints are a versatile and straightforward method for joining materials in various applications.

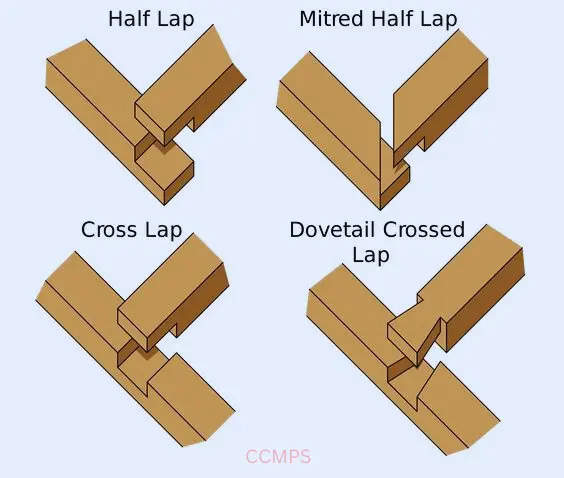

Types of Lap Joints

Basic Lap Joint

A basic lap joint is the simplest form of lap joint, where two pieces of material are overlapped and fastened together at the point of overlap. This joint provides a bit of gluing area but is not incredibly strong and can fail under torsion or torque. Basic lap joints are commonly used in wood framing roof construction, where they can be quickly assembled and later reinforced with additional boards, such as collar ties.

Half-Lap Joint

A half-lap joint involves removing half the thickness of each piece of material where they overlap, creating a smooth, strong connection. This joint is more secure than a basic lap joint and is commonly used in woodworking projects and cabinetry. Half-lap joints can be formed using hand or power tools, and they provide a larger surface area for glue and added lateral strength to the joint. They are popular in construction where a plywood gusset can be nailed to the joint area for additional strength.

Mitered Lap Joint

A mitered lap joint is a variation of the lap joint where the ends of the overlapping pieces are cut at a 45-degree angle, creating a clean appearance and added strength. This joint is commonly used in woodworking projects and cabinetry, where aesthetics and a secure connection are important.

Cross-Lap Joint

A cross-lap joint is a type of lap joint where the overlap comes in the middle of one or both pieces, forming a corner rather than at the ends. This joint is also known as a T-joint or T-lap and is commonly used in woodworking projects and cabinetry where a strong corner connection is needed.

Dovetail Cross-Lap Joint

A dovetail cross-lap joint is a variation of the lap joint where the ends of the overlapping pieces are cut in a dovetail shape, providing added strength and visual appeal. This joint is commonly used in woodworking projects and cabinetry, where a visible lap joint is desired or precision woodworking skills are to be showcased.

Scarf Lap Joint

A scarf lap joint is a type of lap joint where the half lap pieces connect end-to-end, creating a linear extension instead of an angle. This joint is commonly used in woodworking projects and cabinetry where a long, continuous surface is needed, such as in structural framing, furniture making, or timber construction.

Some Common Mistakes to Avoid When Making Lap Joints

When making lap joints, there are several common mistakes to avoid:

- Inaccurate Measurements: Measuring the size and position of the lap joints incorrectly can lead to a weak joint or misaligned pieces. It’s crucial to measure and mark the wood precisely before cutting.

- Improper Cuts: Cutting the lap joints at the wrong angle or depth can result in a poor fit and reduced strength. It’s essential to use the correct tools and techniques to ensure clean, accurate cuts.

- Insufficient Glue: Failing to apply enough glue to the lap joint can result in a weaker joint. It’s important to apply a sufficient amount of glue to ensure a strong bond.

- Uneven Pressure: Applying uneven pressure when clamping the lap joint can lead to a weak or misaligned joint. It’s important to apply even pressure to ensure a tight fit.

- Inadequate Reinforcement: Lap joints can be weaker than other types of joints, so it’s essential to reinforce them with nails, screws, or dowels to ensure proper strength and durability.

- Poor Alignment: Lap joints can be difficult to align properly, which can result in a weak joint that may come apart. It’s important to take the time to ensure proper alignment to create a strong joint.

- Using the Wrong Materials: Using the wrong type of wood or fasteners can result in a weaker joint. It’s important to use materials that are suitable for the specific application and environment.

- Rushing the Process: Taking the time to measure, cut, and assemble the lap joint correctly is essential for creating a strong and durable joint. Rushing the process can lead to mistakes and a weaker joint.

- Ignoring Imperfections: Lap joints tend to show any imperfections in the wood, so it’s important to ensure the wood is smooth and free of any defects before beginning the project.

- Not Test-Fitting the Joint: Before gluing and assembling the lap joint, it’s important to test-fit the joint to ensure a snug fit and proper alignment. This can help prevent mistakes and ensure a strong joint.

Advantages And Disadvantages Of Using A Lap Joint In Carpentry

Advantages

- Increased Rigidity: Lap joints offer more rigidity compared to other types of joints, making them ideal for heavy-duty projects.

- Ease of Construction: Lap joints are relatively easy to construct, requiring fewer tools and less effort compared to other types of joints.

- Concealed End Grain: Lap joints can conceal the end grain of the wood, providing a nicer finish for the project.

- Gluing Surface: Lap joints provide a larger gluing surface, which can make them stronger and more durable than other types of joints.

- Dismantling and Reassembly: Lap joints can be easily dismantled and reassembled, making them ideal for projects that need to be taken apart and put back together again.

Disadvantages

- Alignment Challenges: Lap joints can be difficult to align properly, which can result in a weak joint that may come apart.

- Imperfections in Wood: Lap joints tend to show any imperfections in the wood, so it’s important to make sure the wood is smooth and free of any defects before beginning the project.

- Strength and Load Capacity: Lap joints are generally weaker than other types of joints and may not be able to handle high loads.

- Space Requirements: Lap joints take up more space than other types of joins, which can make them prone to movement and vibration.

- Skill Requirements: Creating a good lap joint requires a high level of skill and precision, which may be challenging for beginners or those with limited woodworking experience.

In summary, lap joints offer several advantages, including increased rigidity, ease of construction, concealed end grain, and a larger gluing surface. However, they also have some disadvantages, such as alignment challenges, imperfections in wood, strength and load capacity limitations, space requirements, and skill requirements. When deciding whether to use a lap joint or another type of joint, it’s important to consider the specific requirements of the project, including the size and weight of the materials being joined, the amount of stress the joint will be under, and the desired aesthetic appearance.